About Us

Advanced Cryogenic Enterprises Inc. (ACE) has been in the business of precision particle size reduction for nearly 20 years.

With a focus on quality, efficiency and customer service, we have taken the business from a 3,000 sqft pilot plant opened in 2008 to two locations with a total of 75,000 sqft.

Proudly, we are an employee owned and operated company that thrives on the ability to do what others can’t, or won’t.

Our ability to use liquid nitrogen in our processes allows ACE to offer precision fine ground materials through our custom built, cryogenic and ambient processes utilizing a variety of types and sizes of equipment. We can process small lab trial quantities to multiple truckloads a week of virgin, recycled, cured and uncured materials.

We look forward to working with you and your team to

Lab Trial Process

Lab trials are an essential part of what we do. We work closely with our customers during this process to best determine their needs. This is done by gathering necessary paperwork, discussing particle size, packaging and testing requirements to develop the right process for your material. Working together ensures a smooth process and that you end up with the most effective solution for your needs.

ACE has the ability to process as little as a few pounds of for theoretical, feasibility trials and then moving to full scale,

viability trials.

If your material needs to be pre-sized, we can granulate it down to proper feedstock for our lab pulverizers. We will then run a closed loop system on our lab unit directly to the separator for precise particle sizing. We can run single batch sizes without secondary screening. Finally, any required testing will be done to ensure the best results.

Production Capabilities

Advanced Cryogenic Enterprises is experienced in many different compounds. We can granulate from 1 inch down to fine ground powders. Our production units can run cryogenically or ambiently depending on the material and size specifications.

ACE can process incoming raw material in the forms of sheets, trimmings, bales, pellets, granulate etc.

ACE is able to handle many different types of material. We currently process cured and uncured rubber, specialty plastics and other non traditional materials. We can process your material or supply you with our sourced raw materials.

Ambient and cryogenic grinding capabilities

Small volumes to multiple truck capabilities

1 inch to Fine Ground Powder

Cured and uncured materials

Tolling or sourced materials

Pulverizing

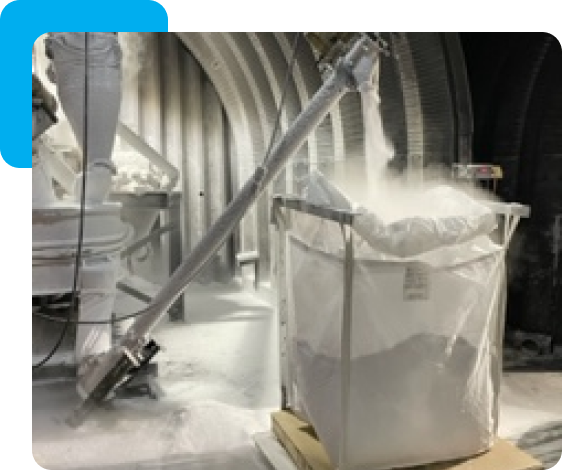

ACE has both ambient and cryogenic pulverizing capabilities. Both types of production lines are set up as a closed loop system from pulverizing to screening to packaging. This prevents contamination and causes oversized material to stay in the system until pulverized to the correct size. Our operators are trained to run an hourly hand sieve and visual inspection to make sure finished product is within spec.

We work with our customers to determine the extent of lab particle analysis and moisture tests that they require on each product run. We can immediately package finished product directly out of the process. This cuts down on any potential contamination or moisture concerns.

Many packaging options are available; these include low melt, polybags, valve bags, gaylords with liners, several sizes of supersacks, boxes or drums to name a few. Certificate of Analysis are available on every order.

Closed loop systems

No contamination

Proper particle size

Immediate packaging in multiple options

Applications

There are many current and developing applications for fine ground powders. We can help you determine the best process for your materials.

Some uses include color chips and flecks, roto and injection molding, extrusions, concentrates or additives, compound fillers, textures for coatings and paints, etc.

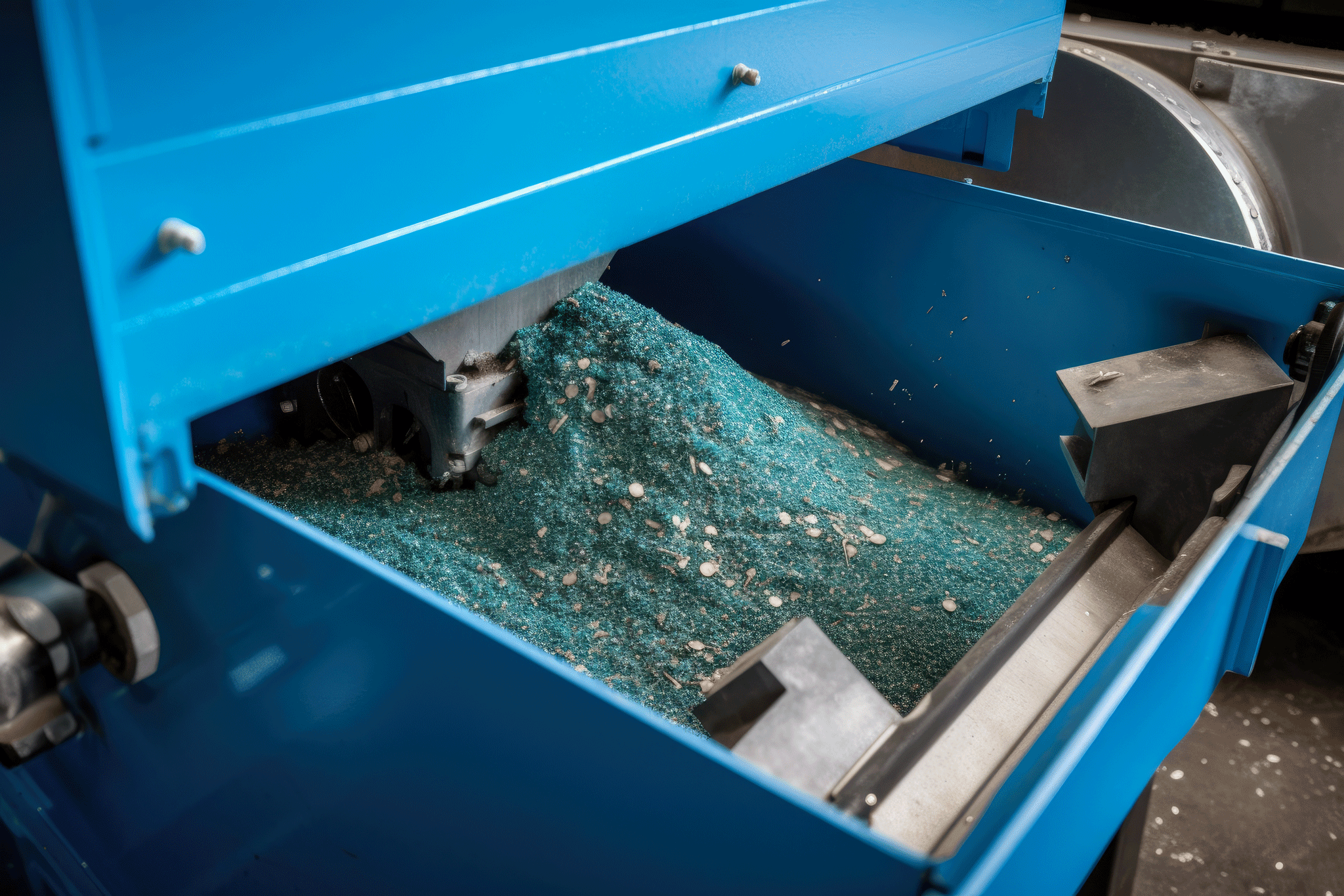

Granulation

This is generally the first step in any recycling process. Our granulation process allows us to take almost any polymer feedstock, cured and uncured, and reduce it to a manageable size, usually for further processing or recycling.

Do you have purging, trimmings or off spec materials that you want to reclaim? We can help

Do you have a polymer that’s not in a form you can use? We can help

With lab scale granulators up to full scale Shredder/Granulator/Elutriation lines there’s not much we haven’t seen. Contact our team and we will work together to determine what will work best for your needs and your operation.

Total Moisture Control For Rubber Manufacturing

You’re no stranger to moisture control challenges in rubber manufacturing. Like many in the industry, you’ve worked with a range of calcium oxide desiccants—products that often share the same essential chemistry.

At Advanced Cryogenic Enterprises, we understand the difference isn’t just in the formula, but in the dependability, customization, and service that come with every order. ACE-CAL is not built to reinvent the science, but to ensure the results you expect, batch after batch.

-

Enhancing Product Quality

Produces uniform texture and premium finish in extruded, molded, and foam rubber. -

Boosts Productivity

Reliable moisture removal increases line speed and throughput while minimizing downtime. -

Reduces Scrap Rates

Maximizes usable yield and lowers waste through consistent moisture management. -

Process Versatility

Seamlessly integrates into extrusion, molding, calendaring, and sponge/foam lines—compatible with EPDM, SBR, NR, NBR, and more.

Typical Specification ACE-CAL 90

| Ignition Residue | 90% | %CaO Available | 85.5% |

|---|---|---|---|

| Specific Gravity | 2.61 | %CaO Minus 325 Mesh | 99% |

| Main Binder | Naphthenic Oil | Appearance | Off-White Powder |